Retrofit: Case Study 3

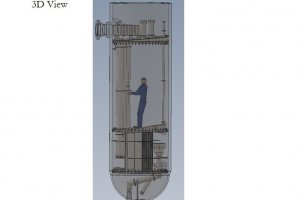

Vessel: HP Separator (F-201), Dia 2.01m

Configuration: Mistmat and baffles in the bottom

Bottleneck: Client had to deal with higher liquid in the inlet gas as well as wanted to obtain HC phase separation in the bottom.

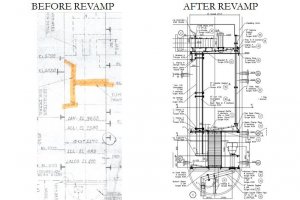

KCH Solution

KCH performed a separation study with respect to the revamp case flowrates in order to determine the ideal modifications. A vane inlet device was installed at the gas inlet to separate the bulk liquid from the inlet gas. The liquid from the top was routed to the new collector tray installed below the inlet device on a full dia clamp ring. The downpipe ensured that the liquid is introduced at the interface in the sump so that the heavy and light liquid will have to travel least distance and avoid backmixing. A platepack was installed on a full clamp ring. Also a new pipe collector was installed in order to have outlet for the light phase.

Post commissioning feedback

The revamped solution met the required outlet gas specifications

Projects go back