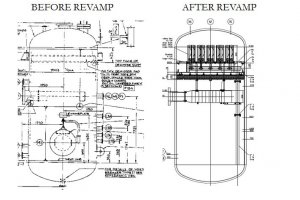

Retrofit: Case Study 2

Vessel: Dehydration Feed Gas KOD (V-1104), Dia/TL - 2m/3.5m is a two phase separator which separates entrained condensate from process gas.

Configuration: Original design config was meshpad and half open pipe. Meshpad was later replaced by vanepack by others.

Bottleneck: Customer wanted to increase throughput by which was beyond the capacity of vanepack. The existing nozzle was too small for the higher flow. Guarantee requirements were 99% removal of droplets 5 microns and above and max allowable pressure drop of 300 mbar.

KCH Solution

KCH Solution: KCH performed a separation study with respect to the revamp case flowrates in order to determine the necessary modifications to optimise the vessel. The inlet nozzle was inadequate and hence KCH installed a split-flow inlet device which aided in slowing down the momentum substantially. The existing vanepack was replaced with KCH High performance HELI-AX cyclones.

Post commissioning feedback

The revamped solution met the required outlet gas specification.

Projects go back