Retrofit: Case Study 1

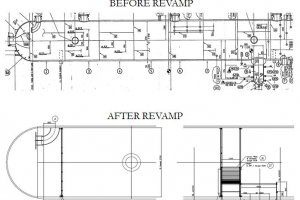

Vessel: Condensate Surge Drum (27-V-107 A) – Dia/TL 3.7m/27.7m is three phase separator which separates gas, condensate and water.

Configuration: Hort vessel with inlet pipe and a boot

Problem: Improper HC condensate/Sour water separation leading to several operational problems.

KCH Optimization

KCH performed a separation study with respect to the revamp case flowrates in order to determine the necessary modifications to optimise the separation performance of the vessel. The inlet nozzle with the pipe was adequate due to low GLR. A KCH crossflow platepack was installed along with a perforated baffle plate in order to clam down the liquid in the inlet section and even distribution of the dispersed phase. The weir height was modified for an increase in height in order to provide a better condensate cut. All the Internals were installed without any hot work using KCH clamp-ring technology.

Post commissioning feedback

Samples of condensate were tested in the lab and GASCO was pleased with the effectiveness of the KCH retrofit.

Projects go back